Precision Edge Prep Systems for Laser Welded Blank Applications

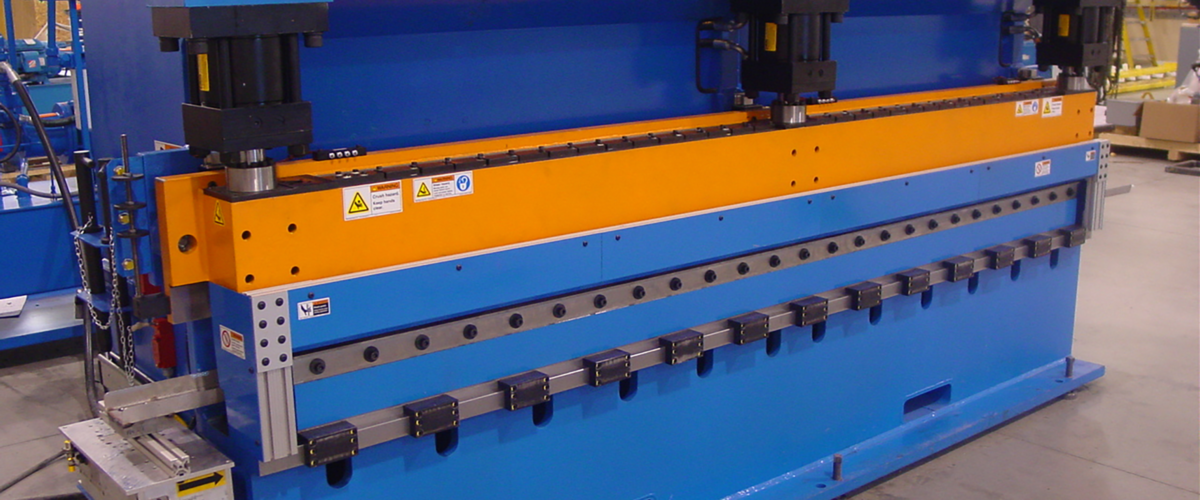

Wayne Trail’s single-sided and double-sided edge preparation systems use our patented clamping-and-cutting approach to help tailored blank suppliers achieve the best possible edge fit-up prior to using the laser butt welding process in linear applications. These high-value systems can be either fully integrated into a new laser welding system, or retrofitted into any existing system.

Conventional shears simply can’t hold up to the rigors of the tailored blank edge-prep environment. Wayne Trail offers both single- and double-sided precision edge preparation systems that ensure tailored blank suppliers can attain the best possible fit-up prior to laser butt welding, day in and day out, year after year.

Every Wayne Trail edge preparation system is fully capable of processing the entire range of material grades used in today’s automotive products – from mild and deep draw quality coated steels, to the most aggressive or exotic grade of AHSS – and even aluminum.

Our Gen III and Gen IV 1x-D single-sided, fixed-knife precision edge preparation systems provide this process step, either offline or integrated into an existing, vintage system. Our single-sided edge preparation system has all the attributes of our proven double-sided machines. This drop-in replacement fits within the footprint of the conventional shear it replaces.

The Wayne Trail Gen III and Gen IV edge preparation systems are truly set-it-and-forget-it machines that require no adjustment and can run millions of cycles between blade maintenance intervals.