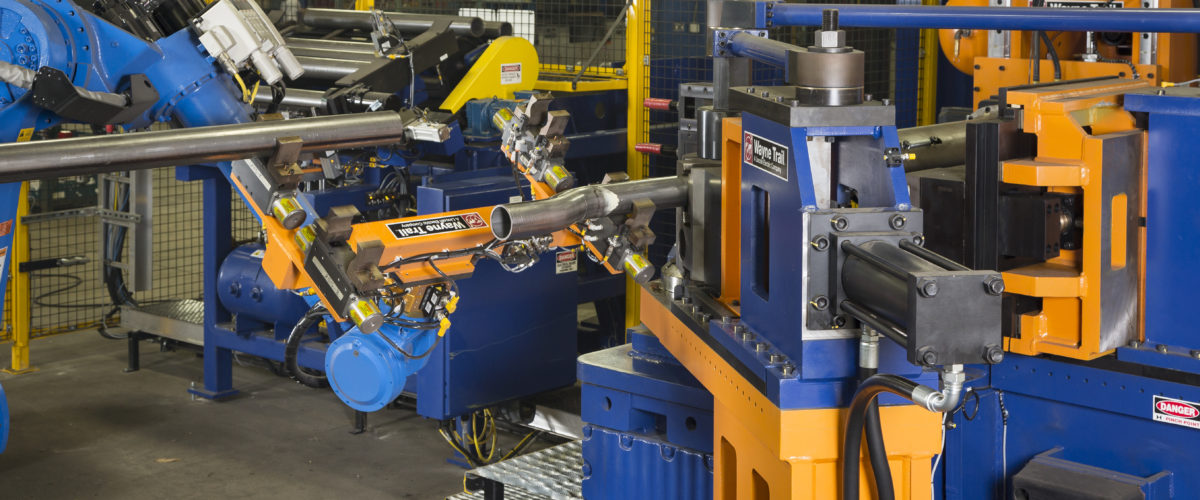

Tube Process Automation

Wayne Trail offers a wide range of flexible, reliable and cost-effective tube process automation solutions to meet the growing mix of applications and markets for tubular fabricated components. Whether you are fabricating parts for automotive, appliances, HVAC, refrigeration, steel furniture, or any other application, we have products and systems to help you maximize top quality throughput.