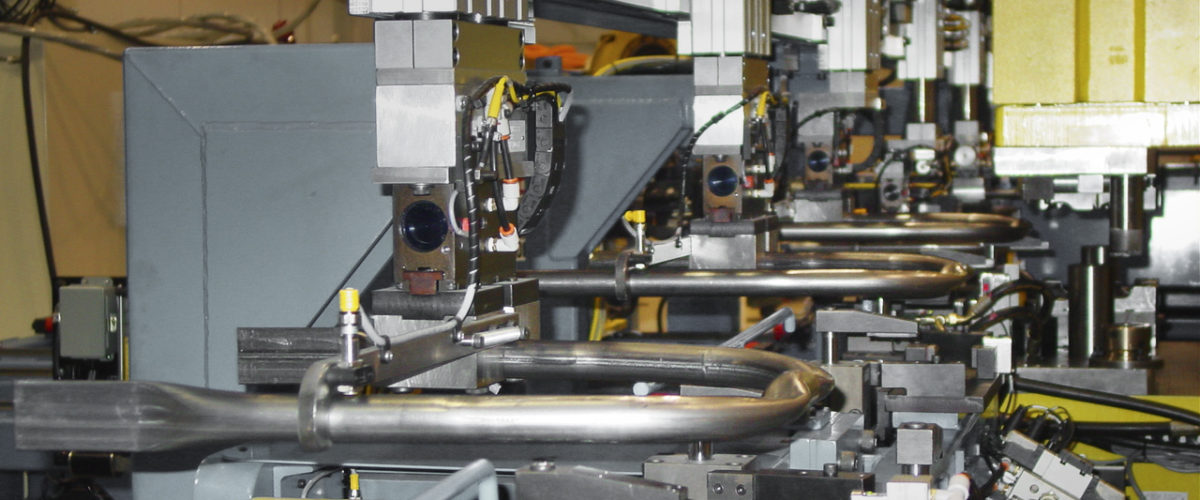

FlexBending® Systems

Flexbending® Tube Bending and Fabricating Systems provide manufacturers with maximum production flexibility by enabling them to run multiple tube products on one machine. These component-based systems are fully programmable and can be easily reconfigured to produce new parts for future requirements. High production rates help lower production costs, while quick changeovers facilitate small lot size runs.

Wayne Trail’s Flexbending® Tube Bending and Fabricating Systems optimize both productivity and flexibility. In many cases, you can feed a raw tube into one end of the Flexbending® system and collect a finished formed tube at the other, ready to be passed on to the next process.

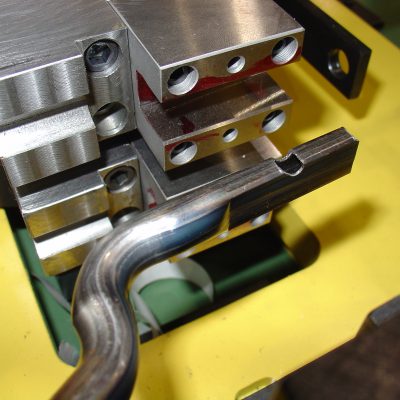

Although each system is custom built to ensure that it precisely meets the application requirements, we use standard system components that typically include:

- Tube hoppers

- Weld seam detectors

- Servo powered benders

- High-performance servo transfers for moving parts from station to station

- Add-on modules for end-forming, flattening, piercing, trimming, welding and assembly operations